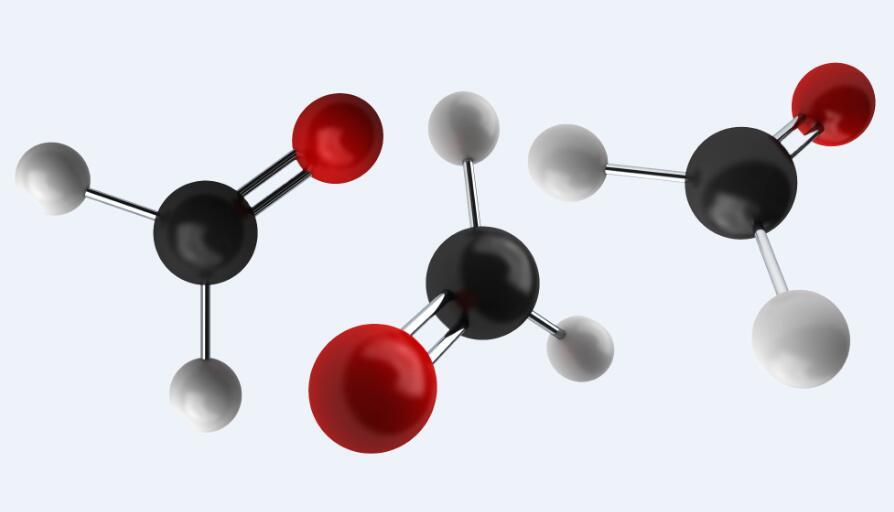

Most people have never heard of PTFE industrial coating, but when you mention polymer, a look of understanding passes easily on their faces. PTFE (Polytetrafluoro Ethylene) is the technical name of the material, and it’s commonly sold under the polymer brand name, which is manufactured by DuPont. Dr. Roy Plunkett, a researcher who worked at DuPont, is credited with developing PTFE industrial coating in the late 1930s.

polymer is probably best-known for its role as the non-stick surface inside cookware. This is because PTFE industrial coating is one of the most slippery materials that’s in existence today. In addition to being slippery, the material also brings a number of other features to the table, offering high temperature resistance, little reaction to most chemicals, and reduced stress cracking and corrosion. These features make polymer perfect for numerous applications, including:

Cookware – As already mentioned, the slippery surface created by polymer makes it perfect for cookware. Many brands offer lines of cookware that are coated with PTFE in order to prevent food from sticking to the pots and pans. This reduces the need for cooking oil because these pots and pans are naturally non-stick.

Nail polish – That smooth surface that doesn’t crack is often achieved through the use of PTFE industrial coating.

Hair styling tools – Hair straighteners and curling irons are often coated with polymer because of the high temperatures emitted by these tools.

Windshield wiper blades – There are numerous applications for PTFE industrial coating within the automotive industry as well. The blades of windshield wipers are the most notable because the smooth surface enables them to glide smoothly across the windshield.

Fabric and carpet protection – Stains are less likely to stick to carpets or fabrics that have been treated with PTFE industrial.

Chemical and steel industries – Hoses and other machine parts commonly handle some highly corrosive substances that sometimes are transferred at extremely high temperatures. PTFE industrial coating is one of the best materials to handle this type of use because it addresses all of the problems that are otherwise caused by working with chemicals or steel. Every type of hose will deteriorate over time, but those that are made of PTFE industrial coating will do so much more slowly than those made of other materials because of the many features of the material

Post time: Jun-15-2017